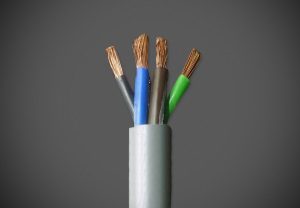

FLEXIBLE WIRING

Flexible Cable Design & Electrical Criteria

The design and proper selection of a cable should take into account environmental conditions, electrical, thermal and mechanical stresses that can be expected, as these all have a bearing on its operating life. All Pioneer Cables, Flexible Cables are designed to suit their application perfectly, thereby ensuring a long trouble free service life.

Conductors

Flexible Cables are made up of conductors consisting of small strands either twisted or bunched. These cables meet either Class-5 or Class-6 of BS-6360.

Pioneer Cables, Flexible Cables utilize high conductivity Copper in accordance with the BS-6360 either finely or extra finely stranded, depending on its intended application and these are bunched or rope laid to provide a flexible conductor assembly with increased mechanical strength. All values for stranding are given as approximate values of the copper used in production.

The BS-6360 specified a maximum DC resistance value for a given conductor cross section. In this way the cross sectional area of the conductor is stated not as geometrical, but as electrically effective cross sectional area determined by the resistance measurement. Thereby, all cables will have equivalent electrical characteristics irrespective of manufacturer or origin of the base copper used.

Insulation

This consists of extruded PVC complying with BS-7655 grade of PVC compound used for insulation is chosen to give good flexibility, resistance to ageing and ability to withstand deformation at high temperatures. It is normally recommended that PVC insulated or sheathed cables are installed at temperatures above 0°C, but special grades of PVC are available that can be handled at lower temperatures and others which are suitable for operation at higher temperatures. Such compounds are more expensive and would only be chosen for a specific purpose.

Sheath

The outer sheath is an extruded layer of PVC compound complying of Type 6 of BS-7655.